Choosing the Right Septa for Your Autosampler Vial Closure

Selecting the right septa for your autosampler vial closures is a crucial consideration for laboratories across various industries. Quality septa promote optimal performance during sample preparation and analysis, influencing the quality and accuracy of test results.

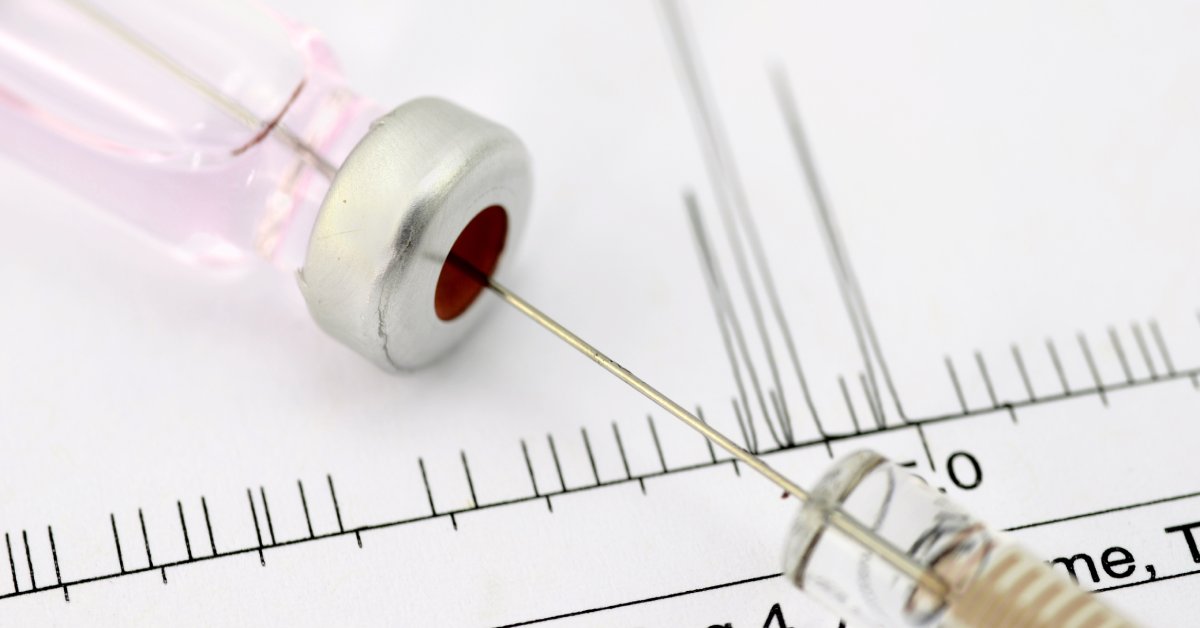

Autosampler vials and their closures, including caps and septa, are integral components in laboratory operations that involve chromatographic analysis, such as gas chromatography (GC) or liquid chromatography (LC).

With various materials and designs available, selecting the right septa can sometimes feel overwhelming. This guide will explore their importance and the key factors to consider when choosing the best option for your application.

What Are Autosampler Vial Septa?

Septa play a critical role in vial closures by forming a tight seal and providing a barrier between the contents of the vial and external contaminants. This component also allows penetration by instruments like syringe needles so you can withdraw or add samples without compromising the contents. The design and material of the septa impact performance, determining factors like chemical resistance and compatibility with various applications.

Why Are Septa Important in Laboratory Applications?

Septa are more than just protective barriers; they preserve the integrity of the samples inside. Quality septa prevent contamination, minimize sample loss due to evaporation, and ensure compatibility with the analytical instruments used.

These features are crucial in scenarios where the accuracy of results is nonnegotiable. For chromatography applications, faulty or low-quality septa can lead to issues such as sample leakage, contamination, and ghost peaks in chromatograms.

Materials Used in Septa Manufacturing

Septa used in autosampler vial applications feature various materials, each offering distinct properties suited to specific needs. Silicone is popular due to its flexibility over a wide temperature range, making it highly versatile. Polytetrafluoroethylene (PTFE) offers exceptional chemical resistance and a barrier against harsh solvents and chemicals. Other materials, such as butyl rubber, may also be useful in applications that demand specific sealing capabilities or enhanced chemical resistance.

Types of Septa on the Market

Various types of septa are available, each suited to different applications. Pre-slit septa allow easy needle penetration, reducing wear and tear on needles, and are useful for applications requiring frequent punctures.

Non-slit septa offer a solid design for a tighter, more secure seal, making them ideal for minimizing sample evaporation and contamination. Double-sided PTFE septa have PTFE on both sides, providing exceptional chemical resistance that makes them highly compatible with sensitive samples.

Key Factors To Consider When Choosing Septa

For the best results, you should carefully evaluate the following septa attributes before selecting one for your laboratory:

Chemical Compatibility

Chemical compatibility is vital to maintaining the integrity of samples for accurate results. Septa materials must resist chemical reactions when exposed to aggressive solvents or reagents commonly used in laboratory processes. Silicone-based septa may not be suitable for certain halogenated solvents, while PTFE-coated septa provide excellent resistance to various chemicals.

Resealability

Resealability is important in applications that require multiple injections or withdrawals from the same vial. Well-designed septa should maintain structural integrity and effectively reseal after repeated punctures for a consistent barrier against air and moisture ingress. This feature preserves the sample’s composition and prevents potential contamination, making it essential for high-precision analytical procedures and long-term sample storage.

Durability

Durable septa withstand multiple injections without excessive wear and tear, which is important for routine or long-term projects. High-quality materials, such as silicone or PTFE, achieve this durability, offering excellent resistance to physical stress and chemical degradation.

Temperature Resistance

Quality septa can withstand a wide range of temperatures for reliability in various analytical processes. The septa must resist deformation or degradation in headspace analysis, where samples deal with elevated temperatures to release volatile compounds. The material should retain its flexibility and sealing integrity in cryogenic conditions to prevent leaks or contamination.

Instrument Compatibility

Ensuring instrument compatibility involves confirming that the septa fit seamlessly with the dimensions and specifications of the lab’s autosampler systems and injection needles. Proper alignment and fit are essential to prevent equipment damage and provide reliable sample introduction during analysis.

Common Problems With Incorrect Septa Selection

Using improperly selected septa can lead to several challenges in laboratory operations, including:

- Leaking samples: Poorly sealing septa can cause sample spillage, leading to inaccurate results and potential safety hazards.

- Evaporation loss: Substandard septa increase the risk of sample evaporation, especially with volatile liquids, affecting the concentration of analytes.

- Instrument damage: Septa that are too hard or made from unsuitable materials can damage syringe needles or clog autosamplers, leading to costly repairs.

Labs can make more informed decisions about their vial closure systems by understanding the potential issues and their consequences.

Benefits of Choosing the Right Septa

HighHi-quality septa ensure precise, reliable results by maintaining excellent sealing and preventing sample contamination or degradation. They contribute to equipment longevity by minimizing wear on needles and sampling systems, reducing maintenance costs in the long run.

Further, the right septa support efficient workflows by allowing for uninterrupted high-throughput processes. Selecting the appropriate septa for lab sample vials is essential for achieving consistent, accurate analytical results and optimizing overall laboratory performance.

Best Practices for Using and Maintaining Septa

To protect septa from environmental factors, always store them in controlled conditions away from excessive heat, moisture, and chemical exposure, as these conditions can compromise their integrity. When installing septa, use appropriate insertion techniques to avoid deformation or damage, which can lead to improper sealing and inaccuracies in results.

Inspect septa regularly for signs of wear, tearing, or contamination, replacing them as needed to prevent issues that may affect your analysis. By following these best practices, you can reduce the likelihood of errors, maintain the reliability of your analytical processes, and optimize the performance of your autosampler vial closures over time.

Industry Applications for Autosampler Vial Septa

Autosampler vial septa are crucial in maintaining sample integrity and reliable analytical results across various industries.

- Pharmaceuticals: The pharmaceutical industry relies heavily on autosampler vial septa for precision and accuracy during drug development, manufacturing, and quality control. These tools are indispensable in achieving compliance with strict regulatory standards.

- Environmental testing: Environmental laboratories utilize autosampler vial septa to accurately analyze pollutants, residues, and trace-level contaminants in air, water, and soil samples. This data is essential for addressing environmental concerns and adhering to regulatory requirements.

- Food and beverage: Quality control in the food and beverage industry depends on advanced analytical procedures where autosampler vial septa are key. They facilitate the analysis of ingredients, contaminants, and nutritional labeling, helping manufacturers comply with safety standards and consumer expectations.

Clinical and biotechnology: Autosampler vial septa are critical in diagnostic laboratories and biotechnological research that rely on precision in biomolecule analysis such as DNA, RNA, or proteins.

Choosing the right septa for autosampler vial closures is essential in ensuring laboratory operations’ success. With many factors to consider, including material properties, sealing performance, and application compatibility, you must assess your needs carefully.

Recent Posts

-

The Role of Desiccants in Protecting Hygroscopic Chemicals

Hygroscopic chemicals readily absorb moisture from the surrounding environment, leading to compromis …May 19th 2025 -

All About Pairing Containers With Corrosive Substances

Handling corrosive substances is critical in many industries, including manufacturing, pharmaceutica …May 12th 2025 -

Why Solvent Purity Is Crucial in the World of Chemistry

When producing accurate and reliable results in chemistry, solvent purity is non-negotiable. Many se …May 11th 2025