Maintaining Vial Integrity During Chromatography Analysis

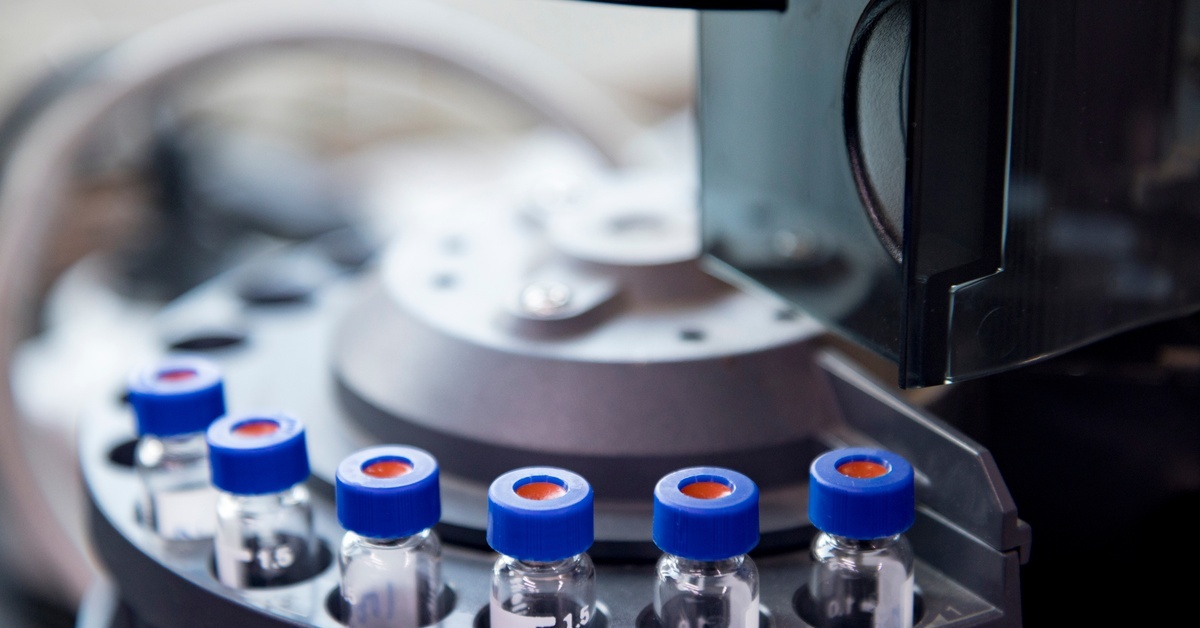

Chromatography analysis is valuable for many scientific and industrial processes, enabling precise separation, identification, and quantification of components within complex mixtures. Its applications include pharmaceutical development, environmental testing, food analysis, and more. However, when pursuing accurate results, vial integrity is often overlooked.

Explore these ways to maintain vial integrity during chromatography analysis. This post will explore common challenges, best practices, and innovative solutions so your laboratory can achieve greater accuracy.

What Is Vial Integrity?

Vial integrity refers to a chromatography vial’s ability to maintain its contents’ physical and chemical stability throughout the analysis process. The efficacy of the vial depends on the seal’s effectiveness, material compatibility, and resistance to environmental factors. A vial with high integrity ensures that the sample remains isolated from contaminants while preserving its intended composition. Additionally, vials must withstand mechanical stress during handling and temperature fluctuations, as even minor breaches in integrity introduce inconsistencies.

Importance of Vial Integrity in Chromatography

Vial integrity is the foundation for reliable results in chromatography analyses. A compromised vial introduces contaminants, causes sample degradation, or yields irregular readings due to evaporation or interactions with external elements.

As chromatography consumables, vials require cleanliness and safety away from sources of contamination since they have a single-time use. Reliable vial performance maintains sample purity, minimizes variance in testing outcomes, and delivers accurate data.

This integrity becomes especially important when working with sensitive analytes or trace-level contaminants. Laboratories stake their reputations on precise outcomes, and inadequate vial integrity may lead to customer dissatisfaction, reworks, or regulatory setbacks.

Factors That Impact Vial Integrity

Several elements influence the integrity of chromatography vials, and understanding these factors ensures optimal performance. The choice of material is paramount, with glass vials being highly resistant to many chemicals, whereas plastic vials cater to specific use cases. Seal quality is also crucial; a poorly fitted or incompatible septum may leak.

Environmental factors such as temperature changes, exposure to humidity, and extended storage time negatively affect the vial, particularly if it is not selected or maintained correctly for the operating conditions.

Common Risks to Vial Integrity

Laboratories often encounter challenges that compromise vial integrity. Leaks caused by improperly fitted caps or weak seals jeopardize the isolation of samples. Physical or chemical interactions between the sample and the vial material lead to unwanted reactions.

Contamination creeps in during manual sample preparation or from equipment, particularly when overlooking protocols. Addressing these risks proactively is necessary to prevent skewed analysis results, additional testing, and operational inefficiencies.

Choosing the Right Vials for Chromatography

Selecting an appropriate vial is integral to protecting vial integrity. Consider the compatibility of the vial material with the solvent, analyte, and storage conditions to limit unwanted interactions. The design and size should also align with the chromatography instrument for proper seating and handling.

Choosing the correct cap and septum is vital for maintaining a tight seal. Balancing these criteria improves vial performance and analysis efficiency, allowing laboratories to handle varying sample requirements confidently. Working with the right supplier of high-quality vials, like our professionals at Ibis Scientific, means you can worry less about the possibilities of a chromatography analysis gone wrong.

Proper Handling Techniques for Vials

Beyond choosing the right vial, handling plays a major role in preserving reliability. Handle vials with care to avoid cracks or deformities. Proper cleaning and sterilization maintain vial integrity during chromatography analysis and upright storage to minimize wear on the seals.

Establishing workflows that include vial inspection before use and adhering to calibrated maintenance schedules ensures long-term reliability. Even minor lapses during handling undermine performance, so attention to detail is paramount.

Use of High-Quality Seal Systems

Reliable seal systems are essential to support robust vial integrity. A high-quality seal prevents leaks while resisting chemical deterioration and temperature extremes. The septum material should be appropriate for the application, as some seals are better suited for highly volatile solvents while others are designed for long-term storage. Routine testing of seal effectiveness reflects good laboratory practices and a commitment to dependable analytical performance.

Routine Inspection and Maintenance of Vials

Regular inspection and maintenance of vials allow laboratories to identify defects or wear and tear before initiating an analysis. This practice involves examining vials for visible damage, ensuring seals remain intact, and verifying that no residue remains inside.

Introducing consistent cleaning protocols improves vial usability and reduces the risk of cross contamination. Vials are an underrated yet indispensable resource, and their proper upkeep ensures they deliver the accuracy and reliability required.

Common Mistakes That Compromise Vial Integrity

A recurring issue in laboratories is the inconsistency of practices during chromatography preparation. Overtightening caps damages seals, while using damaged or unclean vials inadvertently risks contamination. Mishandling vials during transport or preparation often leads to errors only noticed when results deviate unexpectedly. Developing clear protocols and offering regular staff training reduces these errors.

After all, when vial integrity is compromised, the consequences extend beyond mere inconvenience. Laboratories may face inaccurate data invalidating experiments or rendering critical compliance requirements unmet.

The financial cost of spoiled samples rapidly accumulates, especially when intricate testing is required. Delays to projects caused by resampling and reanalysis create additional stress on teams and increased scrutiny from stakeholders directly dependent on timely results.

Technological Advances in Vial Design and Materials

Modern vial materials and design innovations have provided new tools for upholding sample stability and accuracy. High-performance vials with improved resistance to chemicals and mechanical stress are becoming standard.

Advanced coatings also reduce chemical interaction risks, while novel seal mechanisms ensure better compatibility across various sample types. Investing in these innovations drives efficiency and reduces risks, presenting a clear advantage for organizations in fast-paced industries.

Chromatography analysis relies on precision and consistency, qualities only possible with a strong commitment to vial integrity. Understanding its role in mitigating risks and leveraging advances in vial technology and laboratories to overcome challenges and streamline processes is critical. A strategically planned approach to vial selection, handling, and maintenance builds the foundation for reliable results and sustained operational success in scientific endeavors.

Recent Posts

-

The Role of Desiccants in Protecting Hygroscopic Chemicals

Hygroscopic chemicals readily absorb moisture from the surrounding environment, leading to compromis …May 19th 2025 -

All About Pairing Containers With Corrosive Substances

Handling corrosive substances is critical in many industries, including manufacturing, pharmaceutica …May 12th 2025 -

Why Solvent Purity Is Crucial in the World of Chemistry

When producing accurate and reliable results in chemistry, solvent purity is non-negotiable. Many se …May 11th 2025